News >

News > Release time:2025-03-25 22:28:25

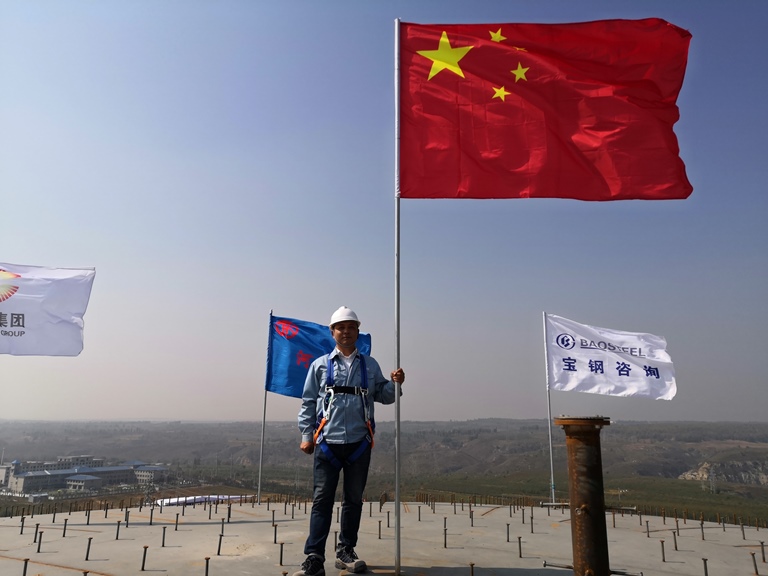

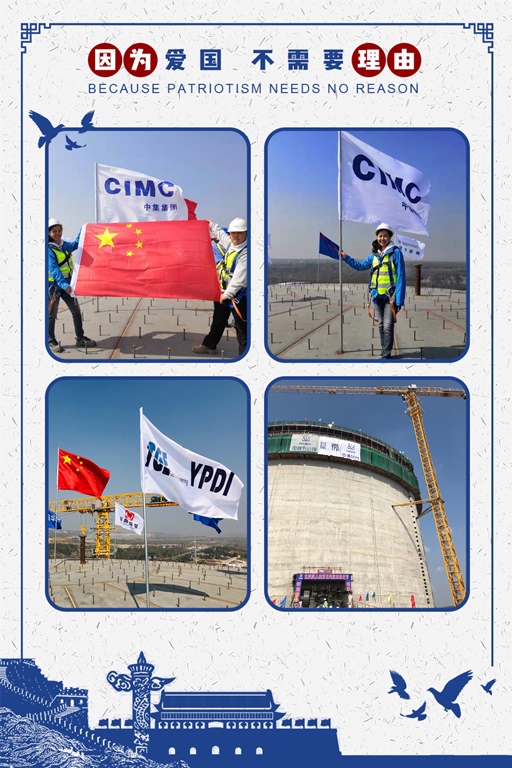

At 11:16 am on September 29, 2019, the gas lifting work for the 120000 cubic meter LNG storage tank project of Inner Mongolia Huineng Coal Chemical Co., Ltd., which was undertaken by our company and TGE in a consortium EPC general contracting manner, was successfully completed.

This project is the largest low-temperature storage tank in Inner Mongolia. Since the start of the pile foundation project in September 2018, the consortium has overcome numerous difficulties, especially the test of severe winter. According to the overall project schedule, the design, procurement, and construction have been carried out in an orderly manner. On the premise of meeting safety and quality requirements, this important milestone of the project was completed 14 days ahead of schedule.

In order to ensure the safe and smooth completion of the work at this node, our company dispatched Assistant General Manager Ye Lin and Construction Management Department Manager and Project Manager Hou Ren'an to the project site to participate in the lifting work together with the TGE team. They personally inspected and confirmed the power system, sealing system, balance system, and communication command system before lifting, and organized mechanical subcontractors to conduct safety technical briefings before lifting. During the lifting process, pay close attention to the various parameters of the gas lift. After the arch reaches the predetermined height, personally climb onto the tank top to inspect the welding work.

The successful completion of the gas lift roof work marks the shift of the project from focusing on civil construction to installation engineering. In the future, we will continue to maintain our excellent work style, overcome difficulties, and complete a series of tasks such as internal tank installation, internal tank cooling, external facility installation, as well as water pressure, airtightness, nitrogen replacement of storage tanks. Throughout the process, we will continue to attach great importance to safety and quality, and ultimately deliver a satisfactory project to the project owner.

Storage & Transportation Engineering

Cryogenic Storage & Transportation

Recruitment phone:025-57050819

Recruitment Email:cet@cimc.com

Phone:025-57053029

Collaboration Email:

cet-marketing@cimc.com

Address: 7.No. 95, Yangcun 3rd Road, Dachang Subdistrict, Jiangbei New District, Nanjing City, Jiangsu Province, China

CIMC Enric Engineering Technology Co., Ltd. Copyright

Official WeChat Account