News >

News > Release time:2025-03-25 22:53:51

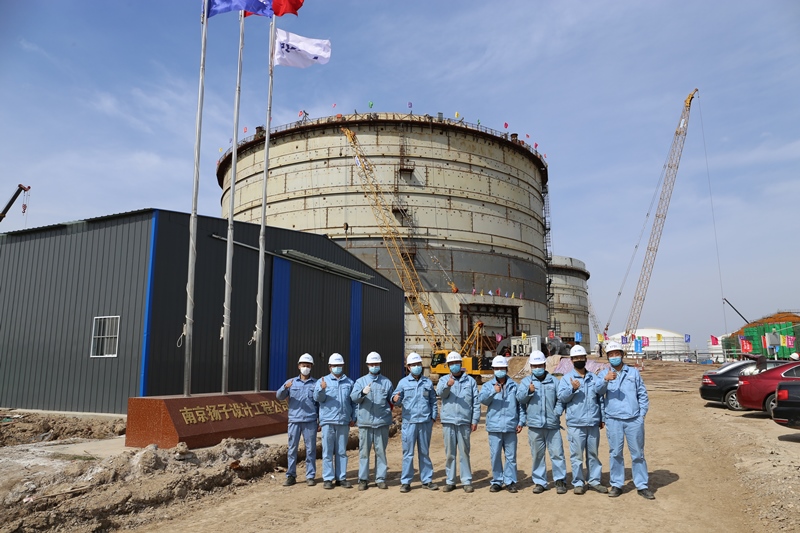

On March 16, 2020, the low-temperature propane and low-temperature butane EPC project of Lianyungang Rongtai Chemical Storage Co., Ltd.'s commercial storage tank area project (Phase II), which was constructed by YPDI, successfully completed the blowing of the first 80000 cubic meter storage tank, marking an important construction milestone for the project and establishing necessary conditions for the next step of construction work. At the same time, it laid a solid foundation for the completion of the entire project.

The Lianyungang Rongtai EPC project is located in the Petrochemical Industry Park of the National East Central West Regional Cooperation Demonstration Zone (Xuwei New Area) in Lianyungang City, Jiangsu Province. The overall scale of the project consists of one 80000m3 low-temperature propane storage tank, one 80000m3 low-temperature butane storage tank, and its supporting storage and transportation process system, public engineering system, etc.

At present, under the influence of the COVID-19, the control in Lianyungang area is still extremely strict. The YPDI project team has overcome many difficulties. All departments of the company actively cooperate, carefully plan, reasonably allocate on-site resources, and implement and complete various preparations for roof blowing. In the early stage of roof blowing, the YDPI project management team organized the owners, supervisors and professional engineers of the construction unit to strictly inspect and confirm the external tank parts of the low-temperature propane tank, tank top parts, and construction tools and facilities used for roof lifting. At the same time, technical and safety briefings will be provided to all construction personnel involved in the roof lifting work, and the leadership group for roof blowing work will be organized to coordinate and command the entire process. It is required that the roof blowing process strictly follow the construction plan, minimize the uncertainty of the blowing process as much as possible, and ensure the success of the blowing process as much as possible.

At 7:58 am on March 16th, the blowing work officially began. The bottom area of the top component of the 80000 cubic meter low-temperature propane outer tank, which has been completed at a height of nearly 34 meters, with a diameter of nearly 60 meters and a total weight of 658 tons, was ventilated and blown for 118 minutes. The edge plate of the tank top was tightly pressed against the bottom of the outer tank pressure ring. Subsequently, two riveting and welding team leaders led 20 welders and 20 riveting workers to carry out the welding work between the tank top plate and the outer tank pressure ring with the cooperation of lifting, quality inspection, electrician, and safety disciplines. The entire welding process lasted about 5 hours. At 3:05 pm on March 16th, the blowing blower stopped running, marking the successful completion of the low-temperature propane tank gas lifting work.

The successful completion of the roof blowing work marks a milestone victory in the development of the project, as well as new goals and challenges. In the future, we will continue to maintain YPDI's excellent style, overcome difficulties, cooperate carefully, innovate pragmatically, and continue to attach great importance to project safety and quality. Ultimately, we will deliver a satisfactory project to the project owner.

Storage & Transportation Engineering

Cryogenic Storage & Transportation

Recruitment phone:025-57050819

Recruitment Email:cet@cimc.com

Phone:025-57053029

Collaboration Email:

cet-marketing@cimc.com

Address: 7.No. 95, Yangcun 3rd Road, Dachang Subdistrict, Jiangbei New District, Nanjing City, Jiangsu Province, China

CIMC Enric Engineering Technology Co., Ltd. Copyright

Official WeChat Account