News >

News > Release time:2025-03-26 09:14:48

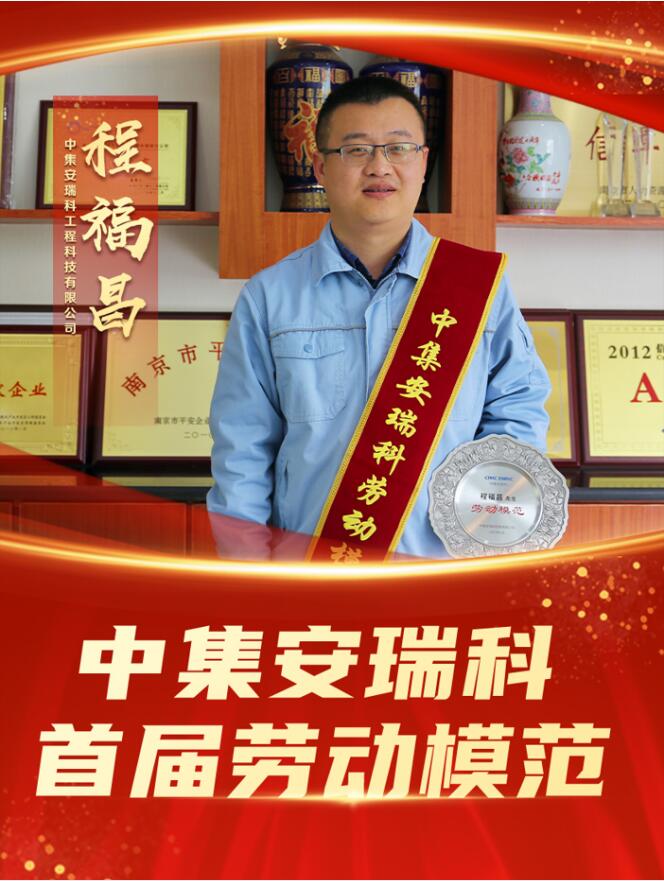

——Cheng Fuchang, the first model worker of CIMC Anruike

Designers are probably familiar with this profession, but I'm not sure if anyone is familiar with the field of chemical designers? In this issue, we will take you into the process room of CIMC Anruike Engineering Technology Co., Ltd. to learn about the charm of "graphic design" in the engineering design industry.

After graduating from graduate school, I chose to join Nanjing Yangtze Petrochemical Design Engineering Co., Ltd. (now renamed CIMC Anruike Engineering Technology Co., Ltd.). In fact, at that time, I could also choose to do research and development and sales, but considering that the company has a certain social influence and my professional expertise can be utilized, I chose this technician job. I am glad that I made the right decision at that time, "said Cheng Fuchang. Since joining CIMC Anruike in July 2013, he has been working at the grassroots level for 9 years and has now become a design management worker.

Entering the workplace for the first time, seize every opportunity to learn

He is highly praised by leaders and colleagues for being proactive, capable, and courageous in taking on responsibilities. Striving for excellence and being meticulous and serious "is the professional label of Cheng Fuchang in the eyes of others. As an assistant designer, Cheng Fuchang often uses weekends or spare time to study past project drawings and design schemes, simulate processes, and draw project drawings. Through self-study, Cheng Fuchang has gradually improved his skills in the design of LNG peak shaving stations and low-temperature storage and transportation processes for liquefied hydrocarbons. Finally, shortly after joining the company, he participated in the EPC contracting project of Shenzhen Natural Gas Reserve and Peak shaving Reservoir. Cheng Fuchang took the initiative to take on the responsibility of project document control. His limited work experience as a novice in the workplace did not affect his progress. He applied the knowledge he had self-taught to practical work, clarified the relationships between various professions and the design process, and laid the foundation for the coordination and management of subsequent design work. Manager Chen Xueyang, the mentor, recalled this past event and described it as follows: "For ordinary people doing document control, it may be about organizing and transmitting materials, and doing a good job in uploading and distributing them. However, he not only did a good job in document control, but also took advantage of this opportunity to understand the process and context of the entire design work, and through the combination of theory and practice, he gained a comprehensive understanding and knowledge of design work. Cheng Fuchang's rapid growth is the result of his hard work

In September 2018, in order to win a certain EPC general contracting project, Cheng Fuchang went south to Shenzhen to study under the leadership of Zhu Shenghua, the general manager of CIMC Engineering. Through communication and learning with technical experts, the bidding plan was gradually optimized. After multiple rounds of polishing, CIMC Engineering finally obtained hundreds of millions of yuan in project orders with its advantages in technology and price. By deeply participating in the delivery of this EPC project, Cheng Fuchang's understanding of the entire liquefied hydrocarbon tank area has made a qualitative leap, and he understands that design work is a team work that cannot be separated from the collaboration and cooperation of various professions. Process design not only requires high professional technical skills, but also the coordination ability between various disciplines in the project is crucial.

Sense of responsibility is the guiding light in the workplace

In November 2020, Cheng Fuchang and others were entrusted with the task of leading the start-up of a low-temperature propane and low-temperature butane project (referring to the first operation of a chemical plant) in Lianyungang. At that time, Cheng Fuchang had no practical driving experience, no fixed driving team, and had to face the test of climate. After calm thinking, Cheng Fuchang quickly gathered colleagues to form a team of 7 people, discussed and formulated a driving plan. After 3 months, the project plan was implemented and the 7-person team quickly immersed themselves in the work. In addition to being responsible for central control operations, project team members are also responsible for external operations such as device inspection, valve start stop, and tanker unloading. At the same time, the driving operation needs to run continuously without stopping in the middle. Project members can only use wheel tactics, with only 2 people in a 7-person team resting at night and all staff on standby during the day. At the end of the year, in the cold winter suburbs of Lianyungang, with an unmanned environment of more than 30 kilometers, accompanied by biting cold winds and sporadic rainfall or snowfall, chemical factories are not allowed to wear raincoats. During inspections and operations at night, the project team can only rely on work clothes and a military coat to endure in the harsh environment of minus ten degrees Celsius for nearly three months. Cheng Fuchang recalled: For us technicians who have been working indoors for a long time, these three months were long and helpless, but we did not back down. We carried the mission of driving smoothly on our shoulders, which was a responsibility, but more importantly, we had to take on it. In the end, the project was successfully driven in one attempt, saving the company over 2 million yuan in driving materials. The success of this project has also laid a solid foundation for CIMC Engineering to independently complete the driving operation project in the future.

Honor is the result of past efforts and the driving force for future progress

Since 2013, Cheng Fuchang has participated in the design work of 5 large-scale EPC projects and 56 large, medium, and small projects. In January 2021, he was awarded the "Excellent Engineering Design Third Prize" by the Jiangsu Provincial Department of Housing and Urban Rural Development. Against the backdrop of the country's strong promotion and advancement of "carbon neutrality" and "carbon standards", Cheng Fuchang applied for a patent "Low temperature liquefied gas storage tank BOG treatment system" (patent number ZL202122653333) and passed national certification in November last year. This patent plays a significant role in the optimization research of low-temperature liquefied hydrocarbon tank area evaporation gas treatment system, the overall process setting of low-temperature liquefied hydrocarbon tank area, and the design of large-scale liquefied hydrocarbon tank area. The social value generated is far greater than the economic benefits.

Behind the achievements are sweat and tears, towering chemical plants and storage tanks, which are totems for the growth and takeoff of chemical designers. Cheng Fuchang, 35 years old this year, has been with CIMC Engineering for 9 years. Since joining the company, he has identified his position and is not afraid of high-pressure work tasks. He enjoys challenging work. He firmly believes that hard work pays off, starting from scratch and accumulating experience bit by bit. After years of polishing, it is still like a sponge absorbing knowledge, burying oneself in practical work, and persistently doing better and more solid work.

Storage & Transportation Engineering

Cryogenic Storage & Transportation

Recruitment phone:025-57050819

Recruitment Email:cet@cimc.com

Phone:025-57053029

Collaboration Email:

cet-marketing@cimc.com

Address: 7.No. 95, Yangcun 3rd Road, Dachang Subdistrict, Jiangbei New District, Nanjing City, Jiangsu Province, China

CIMC Enric Engineering Technology Co., Ltd. Copyright

Official WeChat Account